[ Home | Staff

& Contacts | HiFi

Playground | Listening tests | DIY & Tweakings | Music

& Books ]

Tutorial for the building of TNT Aircoil MKII Interconnects

A detailed explanation on how to build them

Product: no compromise DIY interconnect cable

Manufacturing cost: between 100 and 250€

Reviewer: Piero Canova - TNT

Italy

Published: March, 2022

Introduction

During recent weeks, after the publication of the article on the

no-compromise Aircoil MkII interconnect cable, I have received several

e-mails requesting clarification on how to build them and where to find

the necessary components. I thought it would be useful to write a small

tutorial to simplify the job for those who want to build them. Regarding

the suppliers let me clarify that in some cases the availability of the

parts isn't continuous and thus it might happen that the suggested

supplier hasn't in stock the component you are looking for. With this in

mind we can start the build.

- PTFE tube: the best diameter is between 9 to 10mm; to avoid crushing

it at the ends do not use scissors, but rather a sharp knife. My

supplier is Freibo Tech Stores in Aliexpress. Remember to ask in the

order to pack the tube in a loose circle avoiding creasing it otherwise,

once creased, you won't straighten it again.

- Mark on the tube the crossing points every 20mm. The first point is

at 30mm from the end of the tube.

- Hold the first silver conductor with a small piece of masking tape

(the kind used in car body shops) placed 30mm from the end of the

tube before the first crossing point. As you can see in the picture

below, the conductor is held parallel to the PTFE tube. The 5N

silver conductor can be found on Ebay or Aliexpress. In the latter,

they have a wide choice of diameters down to 0,1mm. The best sources

are GD-Parts Audio Store or Papri Audio Store.

- Now we can start winding the silver wire around the PTFE tube

with the wire crossing the points we previously marked on it.

Essentially, we have a spiral that makes a complte turn around the

tube each 20mm. Use a small piece of masking tape each 5-6 turns

to keep the spiral in place. Take good note of the winding

direction: in the picture, it is counterclockwise and you will

need to remember this when you place the second wire.

- Now we must insulate the first conductor with the PTFE tape.

In order to ensure there is no short circuit, you must use three

layers of tape. In DIY shops there are several widths: use the

widest you can find since in this way you will cover the whole

tube in fewer turns.

- Mark again the crossing points, this time on the PTFE tape.

Fasten the end of the second conductor again with a small

piece of masking tape 30mm from the end, but on the opposite

side of the first wire.

- Now we can wind the second conductor as we did with the

first, passing over the first at the crossing points. Since

the first conductor was wound in an anti-clockwise

direction, the second must be clockwise so they will overlap

crossing on the marked points.

- Now we can cover the second conductor with a second

layer of PTFE tape. We can now insulate the conductors at

the ends with some heat-shrink. Hold down the two

heatshrink covered conductors with some masking tape. Here

below you have a picture of how the cable should look at

this stage.

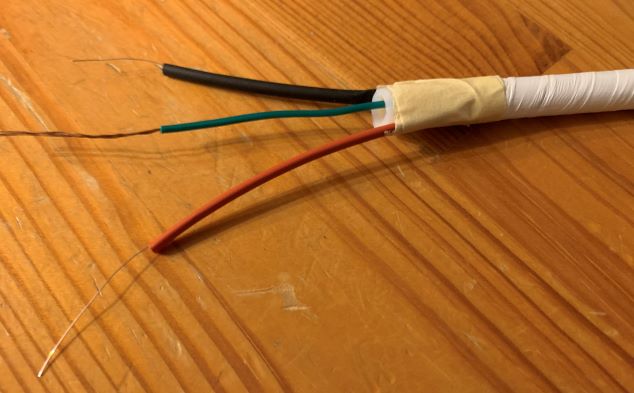

- Now we can insert the third conductor inside the

tube.The length should be some 10cm longer than the PTFE

tube on both ends. I have received several questions on

the kind and quality of this wire. I am using some

conductors coming from another disassembled cable; the

quality is secondary and you can use both solid or

multistranded conductors. Just don't use a conductor too

thick to avoid problems of stiffness or during

soldering. A color of insulation very different from the

heat-shrink over other two conductors will help in

minimizing mistakes. I have chosen black for live, red

for return and green for the inner collector.

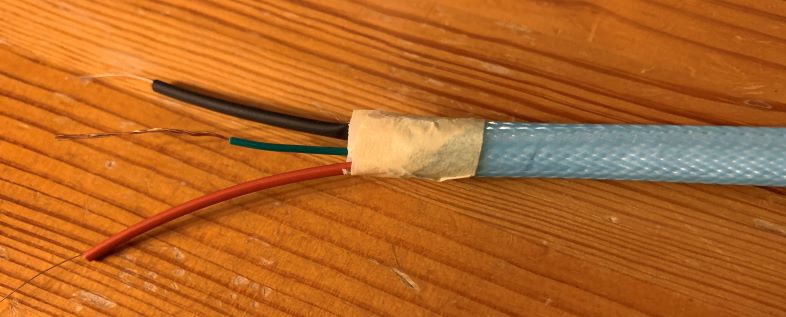

- Now we can protect the cable with a braided cable

sleeve. You can buy this on Ebay, Amazon, or in DIY

shops. Choose the color you like in order to have a

nice finish of the cable. Dark colors cover much

better what's inside while pale ones tend to allow you

to see the contents. This pale blue was recommended by

my daughter who told me it is very trendy this year.

- Finally, to cover the sleeve and keep the

conductors tidy use a second piece of heatshrink.

You can find several colors and I prefer to use red

and blue for the two channels so I can identify them

at first glance particularly when using XLR

connectors which don't have any color markingon

them. Depending on the type of cable you are

building it will be convenient to add some sheath to

hold together the three wires. Normally Cannon

connectors prefer thin wires, whie RCA connectors

where the connector is fixed through a small screw

pushing on the cable, prefer larger diameters in the

7mm range.

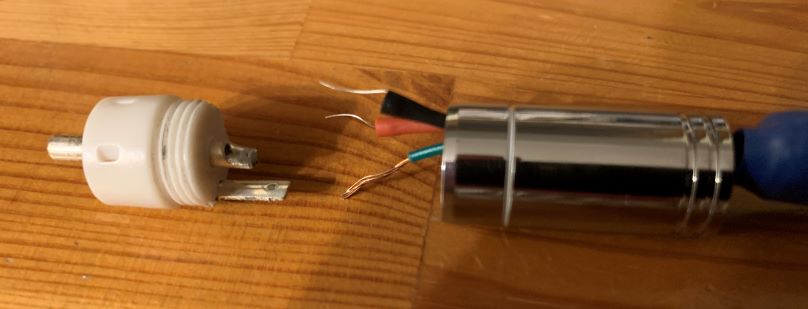

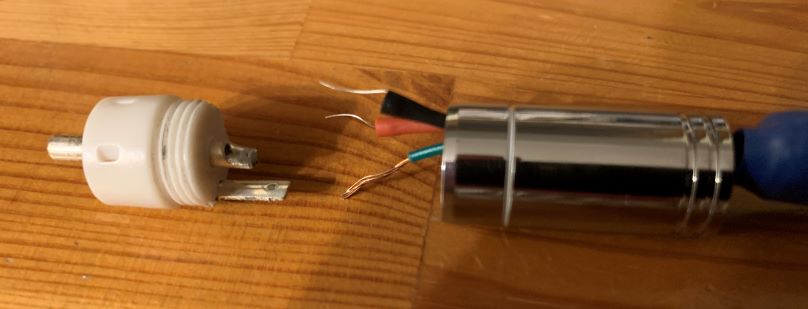

- Connectors: if you want to build a single-ended

interconnect with RCA connectors then you will

connect the wires as follows: black which we will

use as positive on the center pinand red on the

side pin. The green wire will be soldered together

with the red, but just on one end of the cable.

Mark clearly on the outer sleeve the end where you

have soldered the green wire; this side must be

always connected to the source component among the

two you are going to connect. The cable we are

building is then directional. On the opposite end

trim the green cable to the length of the PTFE

tube and block it with some blue-tack or alike so

it won't rattle. Please remember before soldering

that you must slide the body of the connector over

the cable; I have forgotten to do this several

times and these are moments in which your

self-esteem isn't at its best. Which is the best

connector for such a cable? Eichmann Silver Bullet

Plug connectors are excellent but also WBT Nexgen

0110Cu give exceelent results and they are more

affordable.

- If instead you want to build a balanced

interconnect then the connection scheme is the

following: black on pin 2, red on pin 3. and

green on pin 1 on both ends. Regarding the

connectors, I prefer the Neutrik NC3MXX and FXX

silver plated. They have reasonable cost and

they perform very well, but if you prefer other

brands they are fine too.

Conclusions

I hope the above clarifies most of the doubts, but if you still have something unclear please e-mail me. The

final question from our readers was, "Can this cable be made with other

types of conductor?". Of course, yes and perhaps you will find that some

OFC or OCC copper better suits your tastes. Enjoy it.

DISCLAIMER. TNT-Audio is

a 100% independent magazine that neither accepts advertising from

companies nor requires readers to register or pay for subscriptions.

After publication of reviews, the authors do not retain samples other

than on long-term loan for further evaluation or comparison with

later-received gear. Hence, all contents are written free of any

“editorial” or “advertising” influence, and all reviews in this

publication, positive or negative, reflect the independent opinions

of their respective authors. TNT-Audio will publish all

manufacturer responses, subject to the reviewer's right to reply in

turn.

![[Find us on Facebook!]](../jpg/fb_small.jpg)

© Copyright 2022 Piero Canova - piero@tnt-audio.com - www.tnt-audio.com

[ Home | Staff

& Contacts | HiFi

Playground | Listening tests | DIY & Tweakings |

Music & Books ]